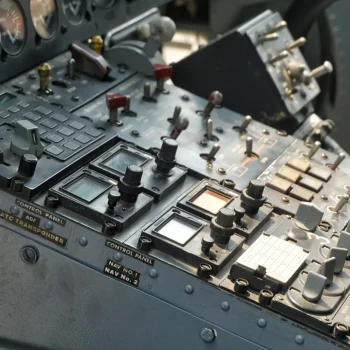

We understand that the product enclosure is a critical component of any design project. It not only protects the internal electronics but also defines the product’s aesthetic appeal and user experience.

Choosing the right enclosure solution is essential to ensure your product is fit for purpose, attractive, manufacturable, and robust.

The decision between custom and standard enclosures depends on factors such as production volumes, budget constraints, and time considerations.

We will guide you through this decision-making process, ensuring that your enclosure choice aligns with your product’s requirements and business objectives.

Consider these basic guidelines when deciding on the type of enclosure for your product.

Pros:

Cons:

Pros:

Cons:

We provide a complete, end-to-end solution, from initial concept through to full production.

FIRMWARE & SOFTWARE DEVELOPMENT

Develop embedded and application software for your hardware.

We provide a complete, end-to-end solution, from initial concept through to full production.

FIRMWARE & SOFTWARE DEVELOPMENT

Develop embedded and application software for your hardware.

INDUSTRIAL DESIGN